Acetate Production

ACETATE TECHNOLOGY USING REACTIVE DISTILLATION

Acetates are products frequently used in the chemical industry. They have a wide range of applications, especially as a solvent in the cellulose, paint, coating and rubber industry.

Along with various technology partners, Fenix has developed processes for the synthesis of ethyl and butyl acetate, as well as for the hydrolysis of methyl acetate, and now offers this acetate technology for licensing. The key feature of the proceses is a reactive distillation technology.

Reactive Distillation provides an edge to the conventional processess as separation of the product from the reaction mixture does not need a separate distillation step, which saves energy (for heating) and materials.

The reaction between components and the removal of the newly formed substances from the reaction zone take place in a single unit.

This technique is especially useful for equilibrium-limited reactions such as esterification and ester hydrolysis reactions

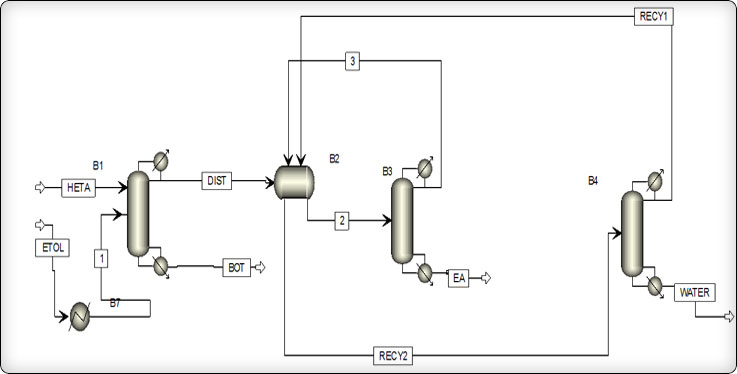

Excess Ethanol and Acetic Acid are fed to the Reactive Distillation Column through a pre heater. The reactive distillation column is followed by two purification columns operating in series to produce Ethyle Acetate.

At the top of reactive distillation colmn, an azeotropic mixture of ethyle acetate, ethanol and water is obtained which is seperated with a Decanter into water and an organic phase.

The major part of Organic phase is purified in further Distillation Column to obtain Ethyl Acetate.

Water from Decanter will be fed to the stripper to recover traces of solvents if any. Bottom water from stripper to be used as feed to cooling tower. Top solvents from stripper will be recycled.