Used Oil Re-refining Technology

In technical collaboration with

Erpek Engineering & Consulting, Istanbul, Turkey

A typical re-refining process is consisting of the following steps.

Pre-treatment: Filtration and de-watering of the waste oil by decantation.

Pre-treatment: Filtration and de-watering of the waste oil by decantation. - De-watering: De-watering and light hydrocarbon removal by distillation.

- Diesel removal: Removal of diesel fraction by distillation.

- Asphaltene removal: Removal of asphaltic fraction by thin film evaporator. High temperature and high vacuum is needed.

- Finishing: After removing water, light hydrocarbons and asphaltic fraction, chemical treatment of the waste oil by solvent extraction or hydrogenation.

- Fractionation: Having different cuts of base oil according to their boiling points.

Propane Deasphalting

This operation is a liquid/liquid extraction process in which propane is used as solvent. The process based on the fact that propane does not dissolve materials with high viscosity while it dissolves low viscosity fluids. Since asphalt is the highest viscosity fraction it precipitates and leaves from the system without dissolving in propane.

This operation is a liquid/liquid extraction process in which propane is used as solvent. The process based on the fact that propane does not dissolve materials with high viscosity while it dissolves low viscosity fluids. Since asphalt is the highest viscosity fraction it precipitates and leaves from the system without dissolving in propane.

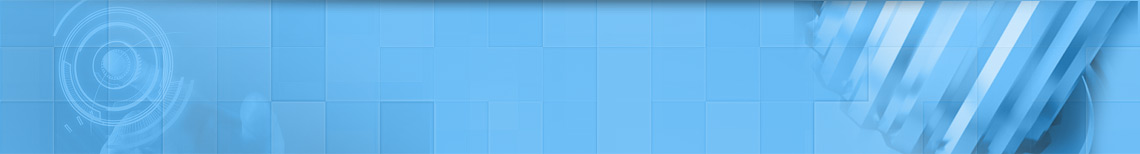

Thin Film Evaporator

Separation of impurities and low volatility, high molecular weight components from mineral oils is carried out in thin film evaporators. It is essential to achieve high temperature and lowest possible vacuum to provide the maximum re-refining of waste mineral oil. In addition, the residence time of the oil should be minimized to prevent it from degradation. Thin film evaporator comprises an upright cylindrical vessel with movable or fixed vertical blades attached to a concentric rotor shaft. Thin layer of liquid formed on the inside wall of the vessel reaches high temperature quickly. Volatile components evaporate and are condensed and collected.

Separation of impurities and low volatility, high molecular weight components from mineral oils is carried out in thin film evaporators. It is essential to achieve high temperature and lowest possible vacuum to provide the maximum re-refining of waste mineral oil. In addition, the residence time of the oil should be minimized to prevent it from degradation. Thin film evaporator comprises an upright cylindrical vessel with movable or fixed vertical blades attached to a concentric rotor shaft. Thin layer of liquid formed on the inside wall of the vessel reaches high temperature quickly. Volatile components evaporate and are condensed and collected.

Short-path evaporators are designed with a condenser placed inside the equipment body. The main reason to carry out different designs for classical and short-path evaporators is the fact that classical types can only be lowered to 1mbar working pressure while short-path evaporators can reach to 0.001mbar internal pressure.

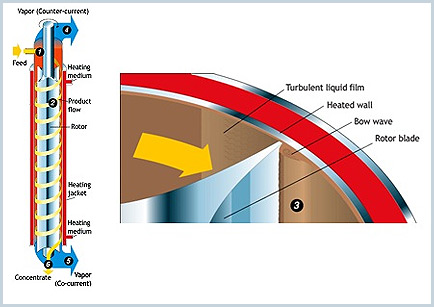

Solvent Extraction

Solvent extraction is a technique based on the separation of aromatics, naphtenics and impurities present in the base oil by the help of a solvent. The first step of the process starts with the contact of solvent and waste oil. In the second step, separation of two phases (extract phase rich in solvent and raffinate phase rich in oil) is formed and at least these phases are subjected to distillation to recover the solvent.

Solvent extraction is a technique based on the separation of aromatics, naphtenics and impurities present in the base oil by the help of a solvent. The first step of the process starts with the contact of solvent and waste oil. In the second step, separation of two phases (extract phase rich in solvent and raffinate phase rich in oil) is formed and at least these phases are subjected to distillation to recover the solvent.

Hydrogenation

Catalytic hydrogenation is known as a modern and successful refining process for a long time. In the process, oil fraction is put into contact with a solid catalyst in high pressure ambient. Proper catalyst and operation condition selections make the process possible to be applied from heaviest to lightest product. Operation conditions can be varied dependent on the necessary reactions and oil fraction subjected to hydrogenation.

Catalytic hydrogenation is known as a modern and successful refining process for a long time. In the process, oil fraction is put into contact with a solid catalyst in high pressure ambient. Proper catalyst and operation condition selections make the process possible to be applied from heaviest to lightest product. Operation conditions can be varied dependent on the necessary reactions and oil fraction subjected to hydrogenation.

As in the hydrogenation operation of petrol refining the main aim of hydrogenation process applied for waste oil refining is the stabilization of un-desired components. It is possible to obtain Class 2 and Type 2 quality base oil according to TS 13369 standard by the removal of sulphur components and increasing the saturated hydrocarbon ratio.

Clay Adsorption

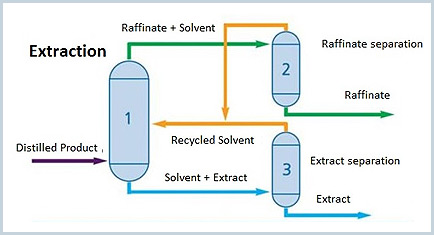

The main aims of the finishing step (Bleaching) in waste oil re-refining process are:

The main aims of the finishing step (Bleaching) in waste oil re-refining process are:

- Removal of contaminants after de-watering and refining steps

- Whitening of dark color

- Deodorizing.

As a simple procedure bleaching is performed in three steps. Oil separated from water, light hydrocarbons and asphaltic residue is placed into a reactor to contact with 2-5% clay mineral. Adsorption period is completed in reactor vessel equipped with necessary mixing blades. Period can be varied according to clay type, mixing efficiency and raw material properties. Mixing period is identified by the help of preliminary tests. Non-dissolving sulfates are formed by the reaction between impurities and additives in waste oil and strong acids found in activated clay mineral. Phase separation is observed after a certain resting time in muddy material. Precipitated sulfates and waste clay is sent to disposal and the suspension is send to filter-press to be leached by the help of a pump.