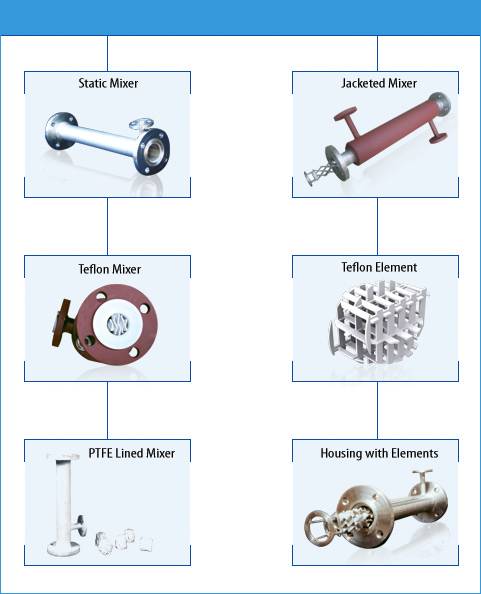

Static Mixers

The components to be mixed are pumped at the inlet of the mixing unit containing static mixing elements. Due to the construction of the mixing elements, the fluids are directed radially outwards and inwards while the forward flow continues. This movement is multiplied by introducing more number of mixing elements. The angle of this movement can also be changed in subsequent elements for better performance. As a result, complete mixing is achieved with the fluid emerging out at the other end.

Materials of Construction: Fenix supplies mixing elements as well as the external housing in Stainless Steel, other Exotic Metals, PTFE and FRP depending on the process requirement.

Types of Static Mixer:

Key Characteristics:

- Mixing low viscosity gases and liquids

- Dispersing immiscible liquids

- Contacting gases with liquids

- Mass Transfer operations and chemical reactions.

|

Key Characteristics:

- Mixing high viscosity gases and liquids

- Mixing & Dispersing liquids

- Homogenizing plastic melts in extruders & injection moulding machines.

- Control of reaction with narrow residence time distribution.

|