METHYL ESTER FRACTIONATION

ABSTRACT

It uses distillation to fractionate. Generally the component parts have boiling points that differ by less than 25 °C from each other under a pressure of one atmosphere. If the difference in boiling points is greater than 25 °C, a simple distillation is typically used.

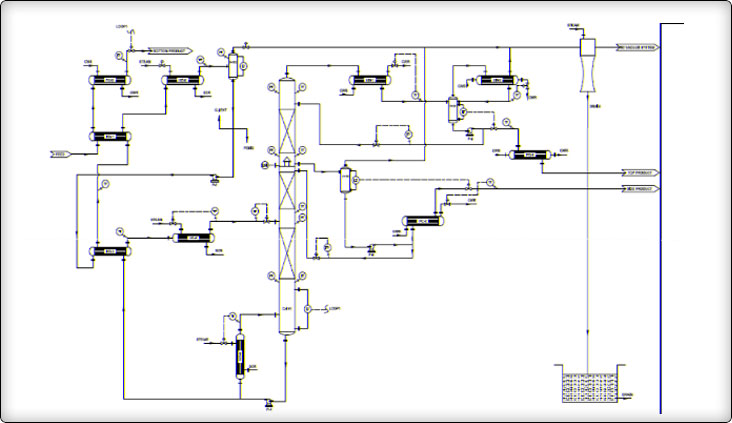

Fractional distillation of fatty acid methyl esters (FAME) is the separation of a mixture into its component parts, or fractions, separating narrower cuts or even individual component to give multiple fractions of higher value. The multistage Fractional distillation can give number of desired fractions by employing two or more columns. Basically, each stage uses the deaerator, heat source, fractional column, Condensing system, and vacuum source. Vacuum system is provide independently for each column to achieve highest vacuum and greater recovery of desired products.

Process Flow Diagram:

Methyl Ester Fractionated Product Applications:

It is widely used in most of Industries Like: Food Processing Industries, Pharmacy, Tobacco Industry, Textile Industry and Cosmetics.

a) Food Processing: Acidulants, Antioxidants, Preservatives, Thickeners, Sweeteners, etc.

b) Pharmacy: Herbs & Spices, Acidulants, Thickeners, Fine Grade Oleo-chemicals, etc.

c) Tobacco Industry: Sweeteners, Fine Grade Oleo-chemicals.

d) Textile Industry: Colorants, construction, Sweeteners, Fine Grade Oleo-chemicals etc

e) Cosmetics: Animal feed Ingredients, Fine Grade Oleo-chemicals, Thickeners, Sweeteners, etc.