Separator Internals

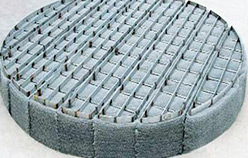

Mist Eliminators

Fenix is engaged in supplying a wide range of internals for industries in Oil & Gas sector. With its process expertise, skill of optimised design & advanced product technology, Fenix offers a full range of separator internals & related services. Fenix’s separation technology & high quality standard manufacturing practices are always engaged in solving industrial phase separation problems with advanced engineering solutions.

Fenix offers a wide range of Separator Internals such as:

This mist eliminator is made from knitted wire mesh sandwiched in between top & bottom support grid. When the entrained drop is passed along with gas through the large surface area of mist eliminator it starts capturing in and impingement in the mist eliminator & the liquid collected on the filaments is then able to drain from the pad under gravity.  Key Characteristics: Key Characteristics:

- It is considered as best option due to its low cost, wide range of applications, simplest design which makes it much more popular.

- These could also be applied with combination of different pads with different surface areas for cases like TEG contactors, even fibre glass demisters are applied to remove moisture below <1 microns.

- Widely applied in tray or packed columns, K.O. drums, Absorbers, strippers, ventury scrubbers, two phase, three phase separators and all gas cleaning applications for removal of fine moisture.

|

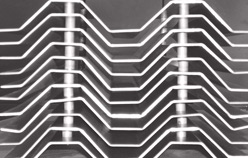

Vane Mist Eliminators

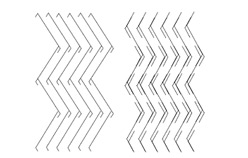

Vane mist eliminators consist of a series of plates or vanes spaced to provide passage for vapour flow and profiled with angles to provide sufficient change of direction for liquid droplets to impact, coalesce and drain from the surfaces of the plates.

Fenix vane mist eliminator provides benefits such as fouling resistant, high vapour capacity, effective removal of high vapour load & low pressure drop. Following are the some different range in vane pack:

Fenix Plain vane style is the simplest design among the vane packs where the vane pack is made from plain plates without any pockets or hooks. Specially designed for larger droplets removal, fouling conditions with either vertical or horizontal gas flow.  Key Characteristics: Key Characteristics:

- Can be easily cleaned by simple water washing.

|

Fenix Hooked/pocketed style is the modified design among the vane packs where the vane pack is made from plates with pockets or hooks. Depending on the process application & performance this style could be manufactured in single or double hook/pocket.  Key Characteristics: Key Characteristics:

- Its specially designed separation channels allow disengagement of liquid from gas flow path and drainage from the vane surface. This separation of liquid from gas flow path helps to improve the efficiency as well as capacity of flowing gas through vane pack, this advantage makes them much suitable for critical applications or wherever modifications is required in existing system.

- Fenix Hooked/Pocketed Vane type is a vane pack for efficient droplet removal and resistance to fouling suitable for high rate horizontal vapour flow.

|