Column Internals

Liquid Distributor and Re-distributor

Packings, whether random or structured, serve the basic purpose of providing intimate contact between liquid and vapour/gas in mass transfer operations. But for effective and efficient performance of packings some more peripherals (i.e. internals) are needed. Fenix has been designing, manufacturing and supplying efficient and economic internals to its customers.

.jpg) Key Characteristics: Key Characteristics:

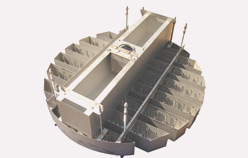

- Channel type distributor is one of the regularly used distributors. Especially successful for structured packing.

- Channel type distributor can be supplied from 200 to 2000 mm diameter. Diameter upto 800mm can be manufactured in single segment and can be manufactured with top trough upto 2 metres diameter in segmented pattern.

- It’s channelised design provided the liquid to distribute evenly & to cover the maximum cross sectional area of the packing.Also provide the low pressure drop due to evenly distribution & vapour flow.

- The distributor can be supplied with bottom holes or with drip tubes.Drip tube can be applied where the fouling conditions are foreseen.

- Liquid load can vary from 1 to 100 m3/m2h.Turndown ratio upto 3:1.

|

.jpg) Key Characteristics: Key Characteristics:

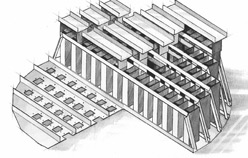

- These distributors are best suited for low to heavy applications available from 700 mm diameter and onwards. These distributors are provided with holes at certain level on side wall of the channels & fitted with baffle plates.

- This construction helps to distribute liquid flow evenly, helps to cover more surface area even for low liquid flow rates.

- In special cases where the flow is very low compared to c/a of column, this distributor helps the best role of distribution by using special distributor facilities. The design of the distributor is in such a way that it sprays the liquid on the baffle plate which helps to spread liquid on surface.

- These distributors are most suitable for fouling applications and even for high viscous applications.

|

.jpg) Key Characteristics: Key Characteristics:

- Construction of this distributor resembles the construction of channel tube type distributor. Channelized construction is applied with holes on the side wall where it is covered with the spiral tube. Such construction helps to apply for viscous liquids & severely plugging application.

- Due to its spiral construction, the liquid sprays on spiral tubes making a thin film layer which makes easy distribution with improved efficiency even for low flow & viscous applications.

- Drip point density can be selected upto 200 m3/m2h depending on packing type

It gives good performance for the liquid loads from 0.7 to 25 m3/m2.h & can be supplied for 300mm to even higher diameter with top trough.

- Turndown can be same as channel type distributor even can be applied for very high turndown upto 10:1 using top trough.

|

.jpg) Key Characteristics: Key Characteristics:

- Chimney tray distributor is applicable for high liquid loads & higher diameter columns. Features of this distributor help it to work as distributor as well as redistributors. Whenever collection & redistribution is required this distributor can be used.

- The design of chimney is very crucial part of the design which is based on liquid & vapour flow and pressure drop requirement.

- For many cases without hole, these trays can be supplied as partial or 100% draw of liquid.

|

.jpg) Key Characteristics: Key Characteristics:

- The spray nozzle type distributor has cone spray nozzles instead of distribution holes for homogeneous distribution of liquid.

- This type has an advantage that liquids containing solid particles can be distributed without plugging problems to the nozzles.

- The Spray type nozzle distributor consists of a main header and laterals with downpipes and spray nozzles.

- Distributor Liquid loading: 2 to 200 m3/m2h

- Distributor Size: upto 8.0 m

|

Key Characteristics: Key Characteristics:

- Pipe Type Distributor is one of the simplest designs. These distributors can be very efficient where the vapour flow is very high as the pipe type construction provides large surface for vapour flow.

- Pipe Type Distributors can handle to liquid loads upto 20 to 25 m3/m2h. These distributors can be applied from 500mm to above size. These can also be designed for smaller sizes but the installation becomes critical.

- Manufacturing can be done as a single piece or arms could be flanged type to pass easily through manway.

|

Key Characteristics: Key Characteristics:

- Pan type distributor provides liquid holdup in the distributor which can operate for very low liquid flow.Vapour passes through a circular or rectangular gas risers.

Distributor can be used even from as low as 100mm & above upto 800 mm column diameter with pan.

- For fouling application pan type distributor can be used with V-Notch Tubes. It can be successfully applied for random Packing.

- Liquid loads can be possible even from 1 m3/m2.hr to 80 m3/m2.hr.

|

Key Characteristics: Key Characteristics:

- Used in packed L-L Extraction columns for continuous and dispersed phase, preventing emulsions at low surface tensions.

|

Key Characteristics: Key Characteristics:

- Trough type distributor construction can be used for very high liquid load & higher column diameter from 900 mm & above diameters.

- Both bottom holes & tube construction is possible in trough type distributor.Top trough distributor the liquid in bottom channels which distribute the liquid evenly on the surface of packing.

- Can be used for both structured & random packing. Liquid loads may vary from 2m3/m2hr to 50 m3/m2hr.

- The simplicity of this design helps to get good seating, better levelling & easiness of installation.

|

Key Characteristics: Key Characteristics:

- These distributors have very small distribution holes and are used usually for smaller diameters and for low liquid loads. Solid impurities are not tolerated.

|

Key Characteristics: Key Characteristics:

- Liquid loading: 5 to 220m3/m2hr

- Size: upto 8.0m

- This can also be used as a liquid redistributor.

|

Key Characteristics: Key Characteristics:

- Features of this distributor resembles with channel type distributor, for special applications where low liquid flow rates are required, we propose to have a special distribution arrangement at the bottom to cover the max. area of packing & to care for low liquid loads even as low as 0.05m3/m2hr.

- The low liquid load can be possible by using special arrangement at bottom of tubes like Spider type distribution. Can handle Gas Load up-to 4.5 Pa^0.5.

|